Land-based Industrialized Recirculating Aquaculture System (RAS) Process and Parameter Design (Part 2)

Recirculating Aquaculture System (RAS) Process Design Principles

Unlike traditional flow-through aquaculture, Recirculating Aquaculture System (RAS) achieves water reuse through advanced treatment technologies and equipment. All components must operate in a scientifically sequenced workflow to ensure efficacy. Key design principles include:

1. Sequential Treatment: Solids → Liquids → Gases

Failure to remove solid suspended particles first will compromise subsequent steps. For instance, biofilter media coated with particles hinder nitrifying bacteria from converting ammonia nitrogen, degrading water quality. Excess organic matter from particles may also overload biofilters.

Treatment Sequence:

1. Solid Particle Removal

- Dissolved Contaminant Removal

- CO₂ Stripping

- Disinfection

- Oxygenation & Temperature Control

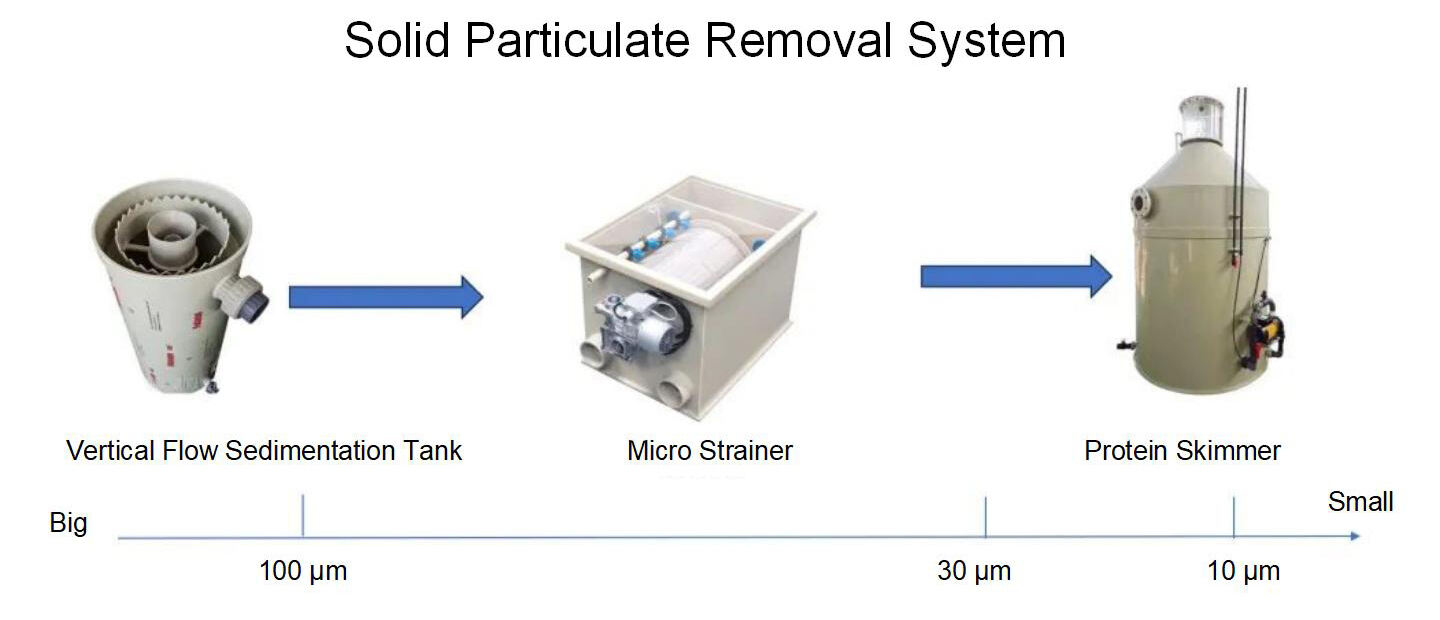

2. Solid Waste Treatment by Particle Size

In the Recirculating Aquaculture System (RAS) system, solid particulate matter mainly comes from the feces of aquaculture organisms and feed that has not been consumed. The treatment of solid waste can adopt different treatment methods according to the particle size, from large to small.

|

Particle size of solid particles |

Treatment Method |

Equipment |

|

Sedimentable particles larger than 100 microns (mainly residual feces) |

Sedimentation |

Vertical Flow Sedimentation Tank |

|

Suspended solid particles between 30-100 microns |

Filtration |

Microscreen Filter |

|

Suspended solid particles smaller than 30 microns |

Foam Fractionation |

Protein Skimmer |

For larger particles with a particle size of over 100 microns (mainly fish manure and residual bait), these particles are sedimentable. To avoid increasing the load on subsequent processes after they break in the system, a precipitation process can be adopted. Vertical flow settler is a device that uses gravity separation to remove sedimentable particles. Through the vertical flow sedimentation process, 60% -70% of solid particles are removed.

After pre-treatment by a vertical flow settler, most of the sedimentable particles have been removed, and the remaining majority are for suspended solid particles between 30-100 microns. This part of the particles can be physically filtered through a microfilter.

After being filtered by a microfilter, the remaining particles are small suspended particles below 30 microns and some soluble organic matter. The particles in this part are mainly separated by foam through protein separator. Foam separation is a common method, which can remove micro suspended particles, soluble organic matter, and has certain functions of increasing oxygen and removing carbon dioxide.

3. Sequential Filtration Before Disinfection

3.1 Impact of Suspended Solids on UV Disinfection

Suspended particles in water can scatter and absorb ultraviolet radiation. This absorption and scattering effect can lead to the consumption of ultraviolet energy during propagation, further reducing the intensity and bactericidal effect of ultraviolet radiation. A study has found a correlation between suspended solids content and the survival of fecal coliforms in wastewater exposed to ultraviolet radiation. Bacteria with surface attached particles are protected by suspended particles, therefore, ultraviolet disinfection can only reduce the survival capacity by 3-4 log10 units.

Suspended particulate matter can limit the penetration depth of ultraviolet rays in water. In clear water, ultraviolet rays can penetrate the water relatively deeply and disinfect water at different depths. However, when there are suspended particles in the water, the penetration ability of ultraviolet rays will be hindered.

Taking a Recirculating Aquaculture System (RAS) pond as an example, in the absence of suspended particulate matter, ultraviolet radiation may be effective in disinfecting water bodies up to a depth of 0.5-1 meters. But if the concentration of suspended particles in the water is high, ultraviolet rays may only penetrate depths of 0.2-0.3 meters, making it difficult for deeper water bodies to be fully disinfected, forming disinfection blind spots. This can lead to the continued growth and reproduction of microorganisms in these insufficiently disinfected areas, affecting the water quality of the entire Recirculating Aquaculture System (RAS) system.

In the absence of suspended particulate matter interference, a certain level of ultraviolet radiation dose (such as 10-20mJ/cm ²) can effectively kill it. But if there are a large number of suspended particles in the water, the ultraviolet intensity may only be 50% -70% of the original. To achieve the same disinfection effect, it is necessary to extend the ultraviolet irradiation time or increase the power of the ultraviolet lamp. Otherwise, some microorganisms may not be completely killed, resulting in incomplete disinfection and increasing the risk of infection by aquaculture organisms.

3.2 Impact of Suspended Solids on Ozone Disinfection

Suspended particulate matter will adsorb ozone in water. Due to the large specific surface area of suspended particles, ozone molecules are easily attached to their surfaces. For example, suspended particles such as feed residues, fecal particles, and microbial aggregates have many active sites on their surfaces that can physically adsorb ozone. This makes it difficult for ozone to effectively come into contact with pathogens (such as bacteria, viruses, fungi, etc.) in water after binding with suspended particulate matter, thereby reducing disinfection efficiency. It's like the disinfection "bullet" (ozone) being intercepted by the "obstacle" (suspended particles) in the middle.

The organic components in suspended particulate matter compete with pathogens for ozone. Many suspended particles contain organic matter, such as incompletely digested proteins, sugars, etc. These organic compounds, like pathogens, can undergo oxidation reactions with ozone. When there are too many suspended particles in water, ozone will preferentially react with these organic substances, consuming a large amount of ozone and reducing the amount of ozone used for disinfecting pathogens. For example, in a Recirculating Aquaculture System (RAS) system containing high concentrations of suspended particulate matter, ozone may first devote most of its energy to oxidizing organic matter on the surface of the particles, while only a small amount of ozone can be used to kill harmful microorganisms in the water.

3.3 Benefits of Filtration Before Disinfection

After physical filtration (removal of suspended solids), biological filtration (removal of soluble harmful substances), and gas filtration (removal of carbon dioxide), the aquaculture water has become very clear. At this time, whether using ultraviolet disinfection or ozone disinfection, the effect will be very good.

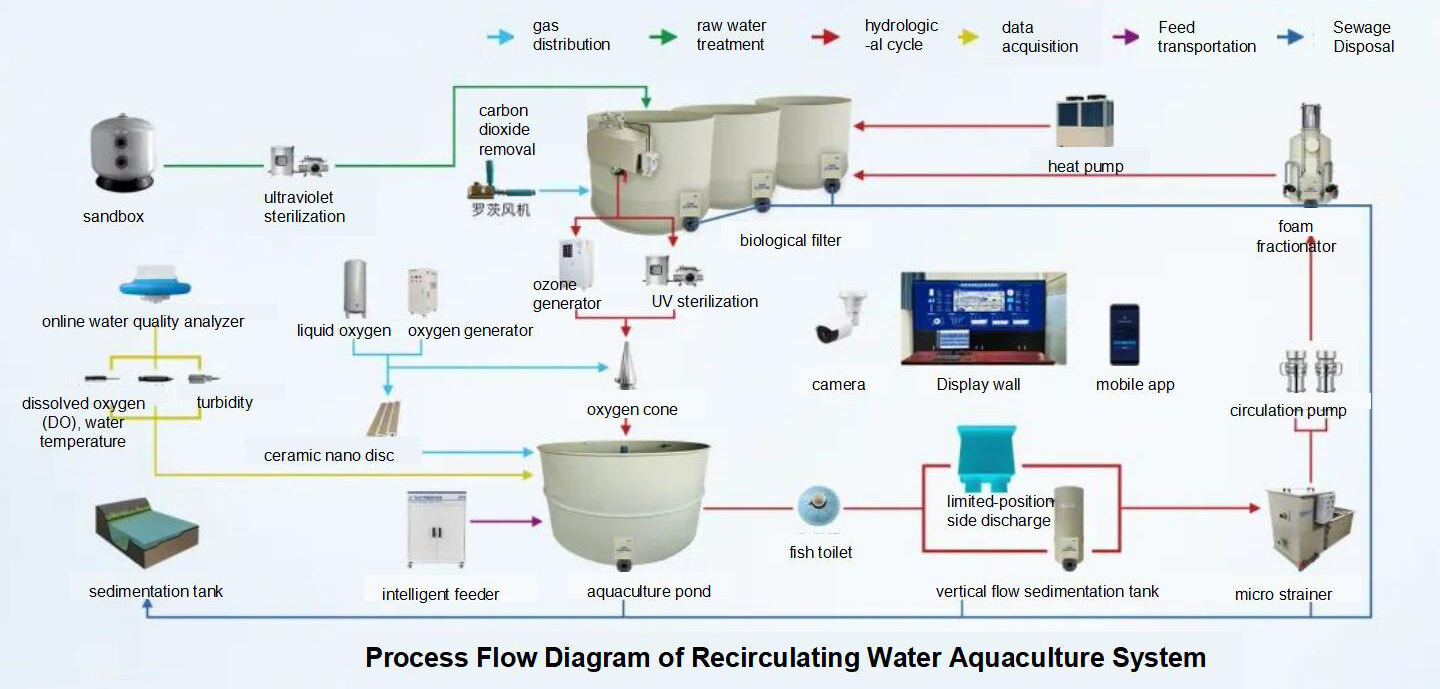

4. Water Circulation Parameter Design

The core of Recirculating Aquaculture System (RAS) is the water cycle. So how to make water circulate? The circulation pump is the core, and its function is like the human heart. The biological filter is the highest point of the entire circulation system, where water flows into various aquaculture ponds through natural atmospheric pressure and then into the pump pool. The circulating pump then pumps water from the pump pool into the biofilter, thereby achieving water circulation.

The circulation pump is so important, so it must be designed with one main and one backup. When the main water pump malfunctions, the backup water pump can be started in a timely manner to prevent breeding accidents.

Circulation Rate Design

The circulation rate of Recirculating Aquaculture System (RAS) is very important. An appropriate circulation rate can ensure uniform water quality in the aquaculture pond. Through circulation, dissolved oxygen, nutrients, and temperature can be evenly distributed throughout the entire water body, avoiding local water quality deterioration. The most important thing is to promote the removal of suspended particulate matter through the circulation of water. The flow of circulating water can bring suspended particles to the filtration equipment for treatment. Adequate circulation rate can improve the removal efficiency of suspended particulate matter and prevent its excessive accumulation in aquaculture ponds. Therefore, the speed of circulation determines the level of suspended particulate matter.

The calculation of circulation rate first requires determining the feeding amount based on the maximum biological carrying capacity, and then calculating the amount of suspended particulate matter produced per hour based on the feeding amount. Then, based on the target value of TSS designed for pond circulating water and the processing capacity of each equipment, calculate the circulation rate.

In summary, the calculation of cycle rate is relatively complex. Based on empirical values, it can be simply used as a reference value to cycle every 1 hours. Taking the cultivation of sea bass in a 1000 cubic meter circulating water body as an example, the cycle frequency is set to a 2-hour cycle. Therefore, the hourly cycle rate is 1000/2=500 tons/hour.

Variable Flow Design

Circulating pump is the equipment with the highest energy consumption in circulating water aquaculture. If the circulation pump is kept in a high-speed circulation state, it will quickly remove waste from the aquaculture water from the aquaculture tank, but the energy consumption is too high. If the circulation pump is kept running at low speed, although the energy consumption is low, the removal rate of waste from the aquaculture tank in the aquaculture water is slow. By installing frequency converters and intelligent control terminals, the variable flow technology can automatically adjust the parameters of the circulating water cycle according to different breeding stages and water quality parameters based on algorithms, achieving variable flow circulation.

Reference Diagram

|

Reference Process Parameters |

|

|

Maximum number of cycles for the circulating water system |

24 cycles/day |

|

Breeding density |

Seawater (e.g., Grouper): ≥50 kg/m³ Freshwater (e.g., Bass): ≥50 kg/m³ |

|

Utilization rate of aquaculture water in the circulating water system |

≥90% |

|

Water exchange rate |

≤10% |

|

UV sterilization rate |

≥99.9% |

Recommended Products

Hot News

-

Is it true that raising fish in high-density canvas fish ponds is more efficient than ordinary ponds?

2024-12-16

-

Advantages of galvanized canvas fish pond

2024-10-14

-

High-density fish farming technology, fish pond cost, canvas fish pond, canvas pond, high-density fish farming

2024-10-12

-

Why choose flowing water high-density aquaculture

2023-11-20