Why choose flowing water high-density aquaculture

The high-density aquaculture system with flowing water and pond aquaculture have five advantages:

1. High yield, fish farming density is between 25kg and 35kg/square meter, which is 3-5 times higher than pond farming;

2. Low cost, one breeding cycle can save 20% of feed costs, reduce 10% of pond construction costs, and save costs such as cleaning fish manure, pumping, irrigation, and lime disinfection in the pond every year;

3. Long service life, 8 to 10 years;

4. Save land resources

5. It can effectively control the spread of fish and shrimp diseases, avoiding the occurrence of disasters where one fish gets sick and the entire pond dies.

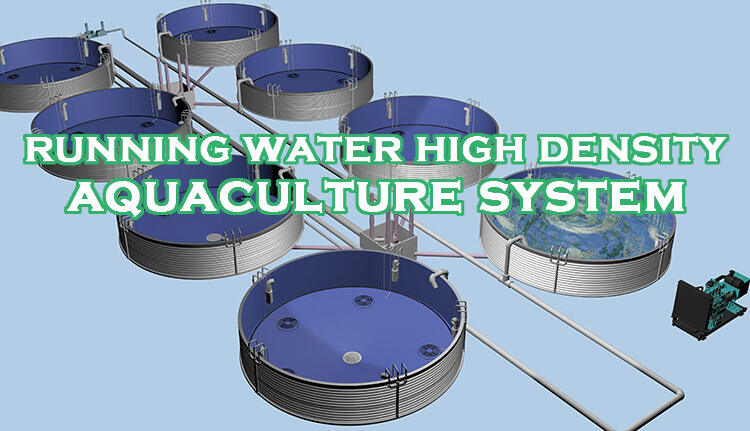

This aquaculture system consists of five major systems, namely: gas supply system, water supply system, power supply system, aquaculture fish pond, and sewage system.

The water supply process of the system is as follows: the deep well pump pumps water from the well to the main water supply pipeline, and then distributes the water to the branch pipeline for discharge into the fish pond.

The aquaculture pool is mainly composed of galvanized sheet, PVC canvas, fish toilet, water pusher, micro nano aeration pipe at the bottom of the fish pool, oxygen increasing plate and other main components. Water pusher A can assist in oxygen increasing, and the exhaust port of B forms a 45 degree angle with the fish pool wall. When supplying gas, it can cause the water in the fish pool to form turbulent flow counterclockwise. Firstly, the flowing water is conducive to the growth of fish and shrimp, and secondly, turbulent flow can better concentrate fish feces at the fish toilet at the bottom of the fish pool, resulting in better sewage discharge effect.

The gas supply process of the system is as follows: the Roots blower inputs 29.4 kilopascals of compressed air into the main gas supply pipeline, then enters the branch gas pipeline of each fish pond, and is distributed to the micro nano aeration pipe at the bottom of the fish pond, the oxygenation plate, and the water pusher on the pond wall through the gas distribution valve, ensuring the oxygen supply in the aquaculture pond.

The sewage system includes: fish toilets, drainage pipes (110mm or 160mm), main drainage pipes 300-500mm, and a smoother conical structure at the bottom of the aquaculture pool.

There are three ways for the system to discharge pollutants: the first is to control the height of the overflow pipe to maintain a balance between the water level of the aquaculture pool and the inflow and outflow; The second method is to discharge pollutants at regular intervals 2-3 times a day. The first section of the riser on the upper part of the overflow pipe is pulled out, and all residual bait and feces at the bottom of the breeding pool are discharged under siphon action; The third method is to open the bottom drainage valve when all the water in the breeding pool needs to be drained.

The power supply system includes: normal market power supply lines. In case of power outage due to special circumstances, one diesel generator is required to prevent fish and shrimp from dying due to hypoxia.

The high-density aquaculture system with flowing water will undoubtedly become the main mode of aquaculture in the future due to its unique advantages.

Recommended Products

Hot News

-

Is it true that raising fish in high-density canvas fish ponds is more efficient than ordinary ponds?

2024-12-16

-

Advantages of galvanized canvas fish pond

2024-10-14

-

High-density fish farming technology, fish pond cost, canvas fish pond, canvas pond, high-density fish farming

2024-10-12

-

Why choose flowing water high-density aquaculture

2023-11-20